3D metal printing

Metal Additive Manufacturing

We realize 3D metal printing on 3D printers of the German company EOS GmbH, which is a leader in the field of 3D printing and Additive Manufacturing.

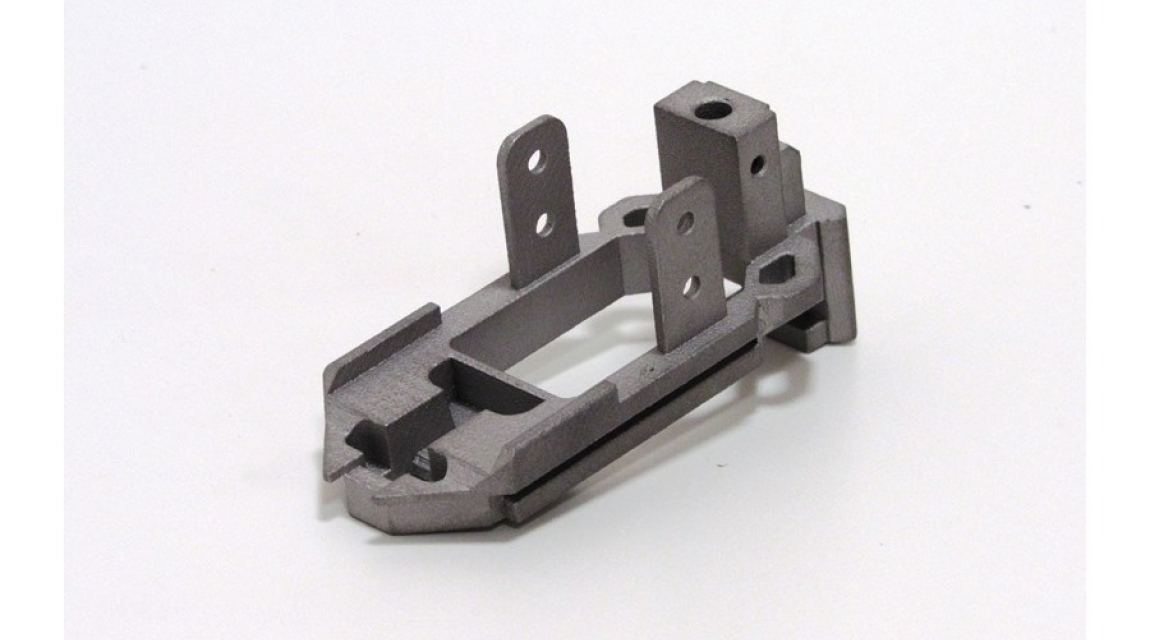

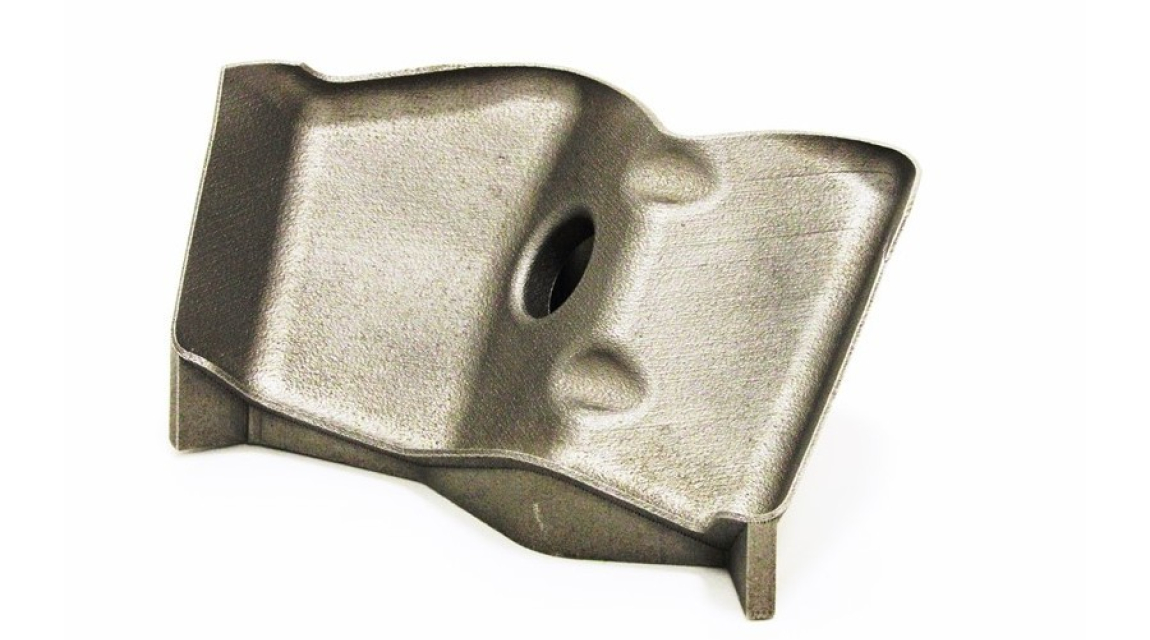

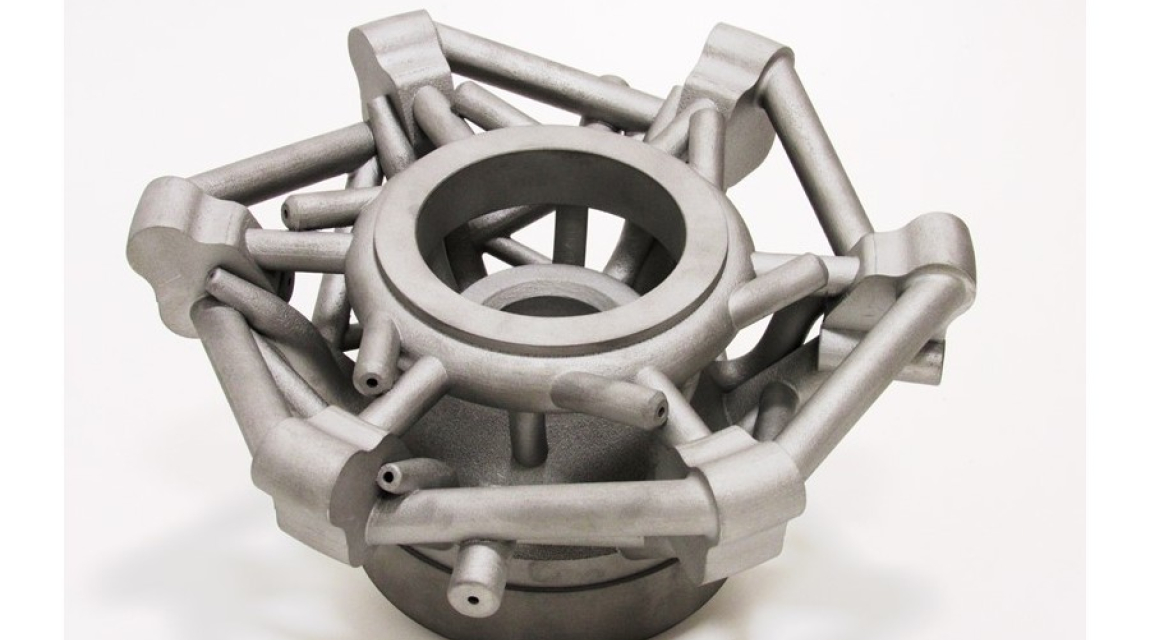

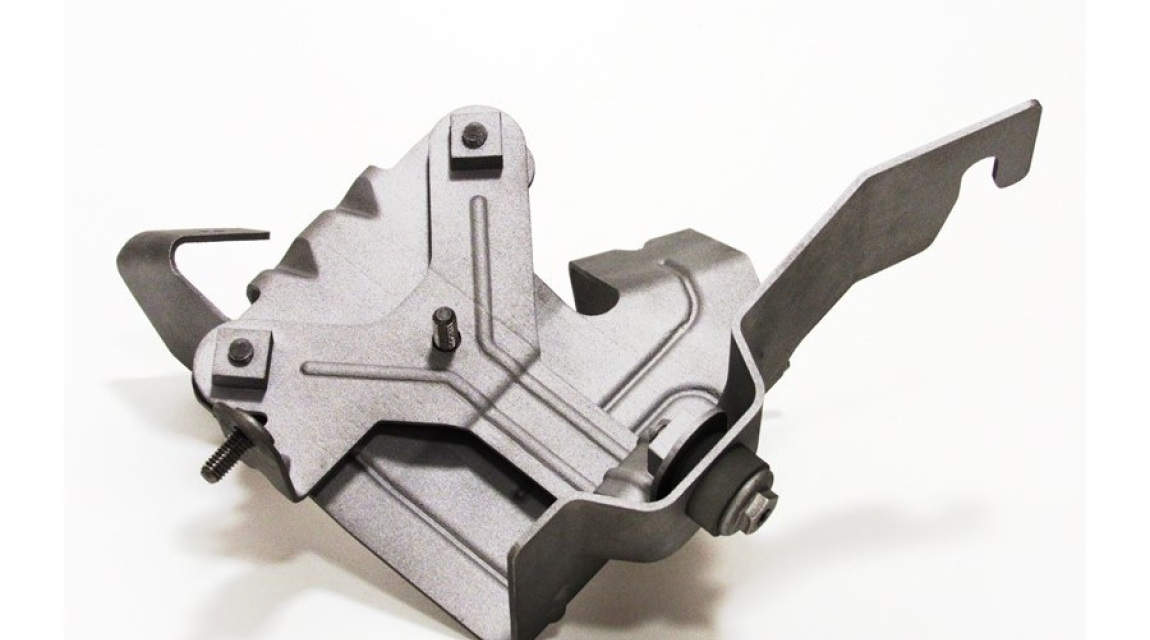

Parts made with DMLS technology are identical in their properties to parts made of classic metal materials on conventional production equipment. These parts can be further processed using conventional technologies (machining, grinding, polishing, welding, etc.).

Technical specifications

- Working space: 250x250x325 mm

- Layer thickness: 0,02 - 0,05 mm

- Laser power: 200 / 400 W

Materials

- Maraging steel - 1.2709

- Stainless steel - 1.4542

- Aluminium - AlSi10Mg

- Inconel - IN718

- Bronze

Advantages of 3D metal printing

How it works

The source is a 3D CAD model

We work with the sent 3D CAD model or we create 3D CAD model according to the customer's specifications.

We can optimize the 3D CAD model to maximize the potential of 3D printing technology.

Data preparation for 3D printing

The source 3D CAD model is data-ready for production.

Material, layer height, position of the part on the building platform, supports, etc. are defined.

3D printing and final finishing

After removing the part from the 3D printer, the part is separated from the building platform, supports are removed and the surface is blasted together.

If required, 3D printed parts can be finished by machining, polishing, heat treating, welding into larger units, etc.