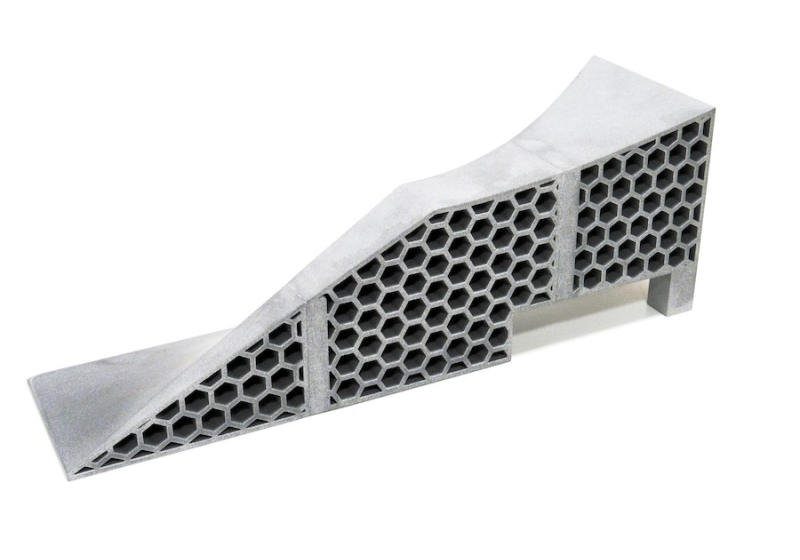

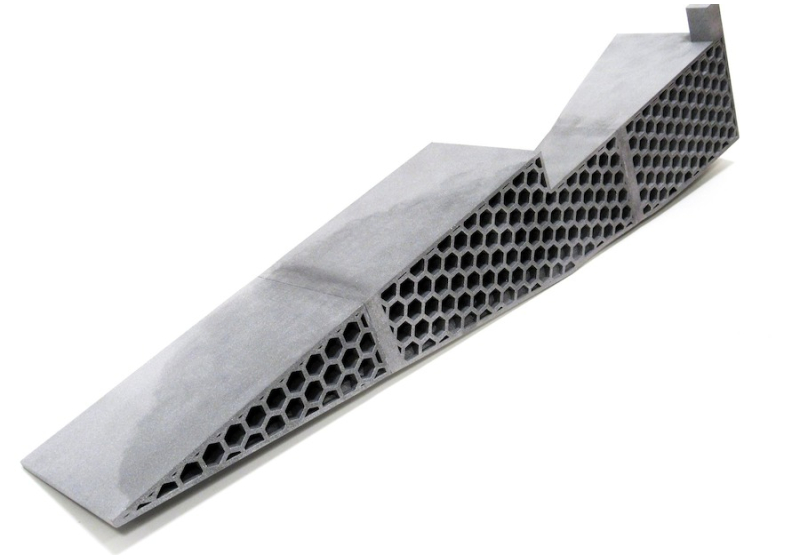

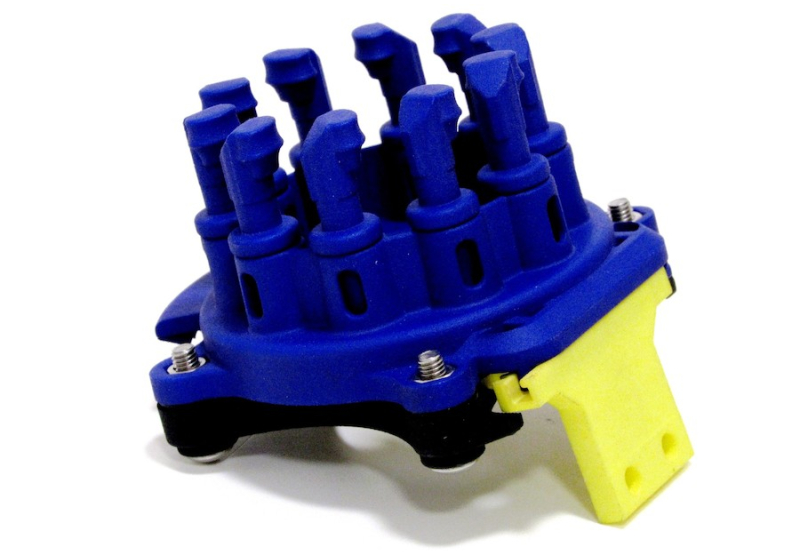

3D plastic printing

3D plastic printing technology

We realize 3D plastic printing on 3D printers of different production principles with a wide range of materials.

3D printing technology:

- SLS - Selective Laser Sintering

- FDM - Fused Deposition Modeling

- SLA - Stereolitography

Technical specifications

- Working space: up to 340x340x600 mm (according to selected technology)

- Layer thickness: 0.02 to 0.36 mm (according to selected technology and material)

Materials

- Polyamide 11 – SLS technology

- Polyamide 12 – SLS technology

- Polyamide 12 + GF – SLS technology

- Polyamide 12 + Al – SLS technology

- Polypropylene – SLS technology

- ABS – FDM technology

- ABS+PC – FDM technology

- Hardened resins – SLA technology

Advantages of 3D plastic printing

How it works

Plastic filament melting

The printer heats plastic filament (e.g. PLA, ABS or PETG) which is melted on a nozzle. The filament unwinds from the spool and continuously moves into the print head.

Layering the model

The nozzle moves over the build surface to deposit the molten plastic exactly according to the digital model. Printing is done layer by layer, usually from the bottom up.

Cooling and curing

Once the plastic is applied, it solidifies quickly to hold its shape. Once finished, the finished part can be used immediately or fine-tuned by sanding, painting or gluing.