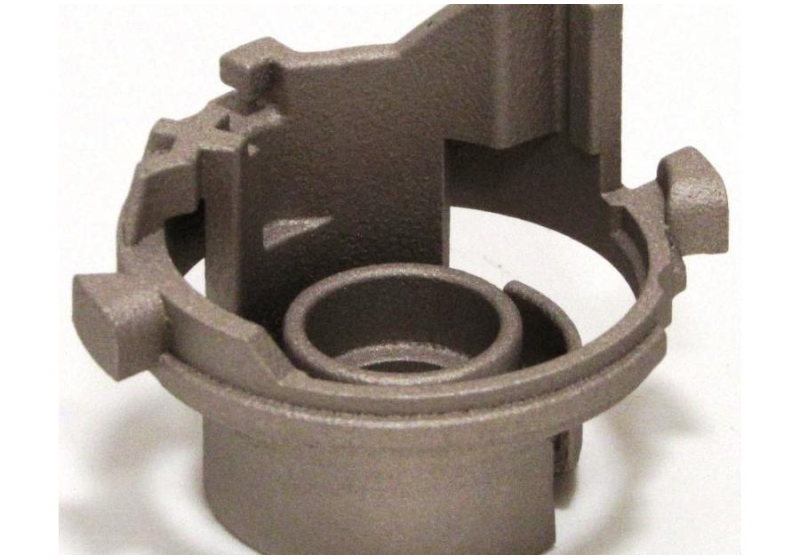

Casting

Vacuum die casting technology

We carry out orders for the technology of vacuum-pressure casting of metals on equipment from the German manufacturer Schultheiss GmbH.

The machine is suitable for the area of prototype to medium series production from non-ferrous metals. Thanks to the use of vacuum technology, we achieve high quality castings. This technology is suitable for the production of complex metal parts from small to medium-sized parts with a size of about 100x100x350 mm.

Technical specifications

- Working space: ∅150x400 mm

- Melt volume: up to 400 cm3

- Product size: approx. 100x100x350 mm

Materials

- Aluminum alloys

- Zinc alloys

- Bronze

- Brass

Advantages of casting

How it works

Production of the "MASTER MODEL"

The master model for moulding can be produced using a mould or 3D printing.

The material is wax or hardened resin.

Mould preparation

From the "Master models" we create a so-called tree, which is formed into a moulding compound.

The mould is cured in the oven and the tree is also melted.

Casting

The cured mould is inserted into the casting machine.

After the casting material has melted, the mould space is evacuated and the casting is then carried out.

After cooling, the parts are finished. The sprue is removed, cleaned, blasted.