Conformal cooling

Conformal cooling technology

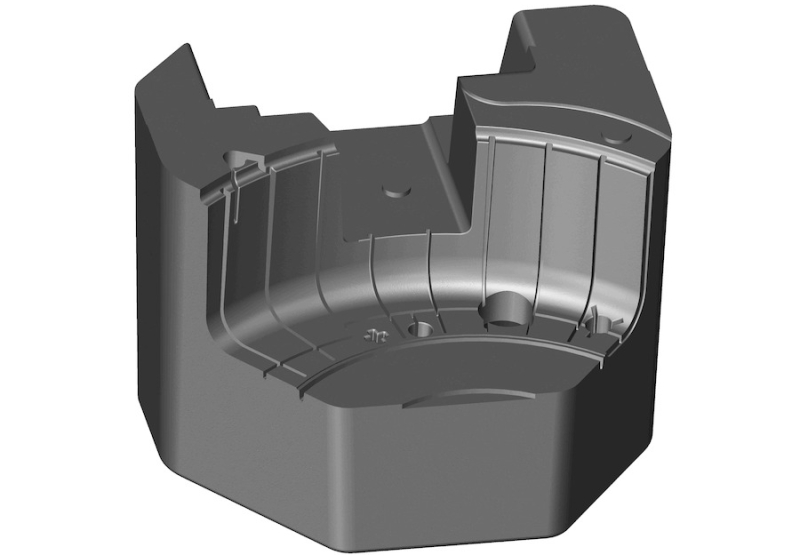

We produce molds with Conformal cooling on 3D metal printers with subsequent CNC machining. Part of our service is also the design and optimization of a Conformal cooling circuit.

Conformal cooling = a cooling circuit designed to copy its surface shape at the shortest possible distance from the molding wall.

Thanks to the production possibilities of 3D printing, we are able to apply the existing more efficient cooling channel system to new molds or mold modifications. Conformal cooling ducts can be treated with an anti-corrosion coating on request.

Technical specifications

- Max. insert size: 250x250x325 mm

- Possibility of hybrid production (ie 3D printing on a prefabricated semi-finished product)

- Heat treatment up to 54 HRC

Materials

- Maraging steel - 1.2709

- Stainless steel - 1.4542

Advantages of conformal cooling

How it works

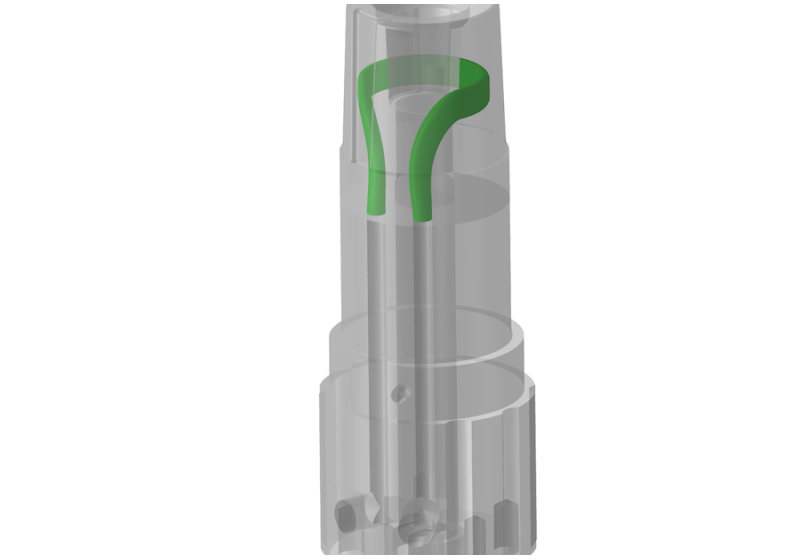

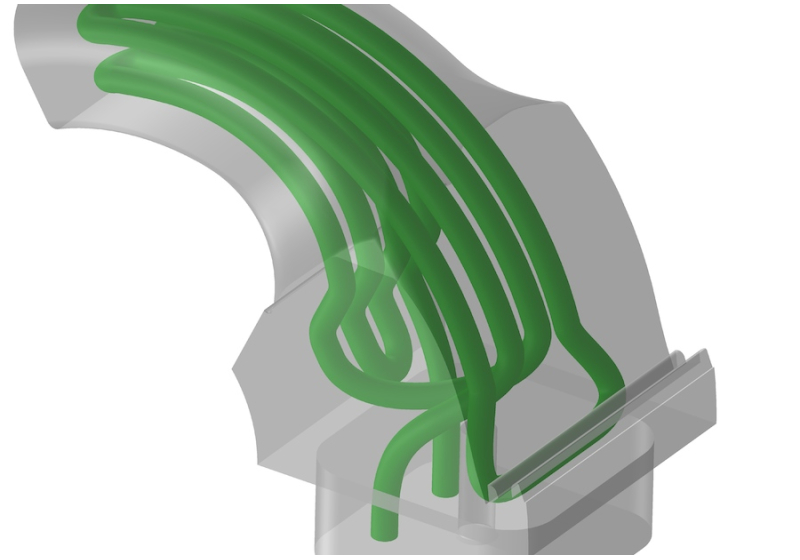

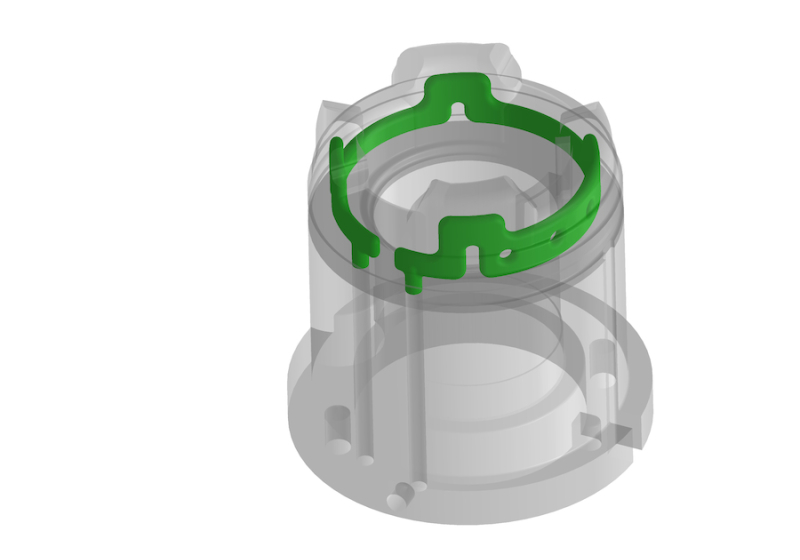

Designing channels according to the shape of the part

Cooling channels are designed to follow the shape of the mould exactly so that cooling is uniform. Unlike conventional drilled channels, these are wound around critical areas.

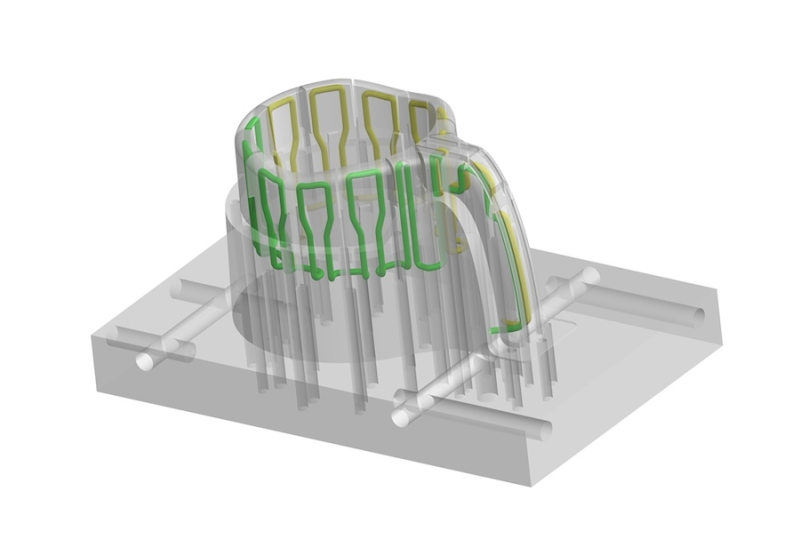

3D Printing Metal Mold

The mold is made using additive manufacturing - often Selective Laser Melting (SLM) technology. This makes it possible to create complex internal channels that would otherwise be impossible to machine.

Finishing and assembly

After printing, the mould is machined (e.g. by milling or polishing), fitted with mechanical parts and prepared for insertion into the injection moulding machine. The result is a shorter cycle time and higher quality mouldings.